Streamlining Logistics with Direct Thermal Printing

Efficient Package Identification

In the fast-paced world of transport and logistics, identifying packages quickly and accurately is crucial for operational efficiency. Direct thermal labels stand out as an essential tool in this sector, offering an efficient and reliable method for package identification. Their durability and cost-effectiveness make them an ideal choice for managing the flow of goods across various stages of the supply chain.

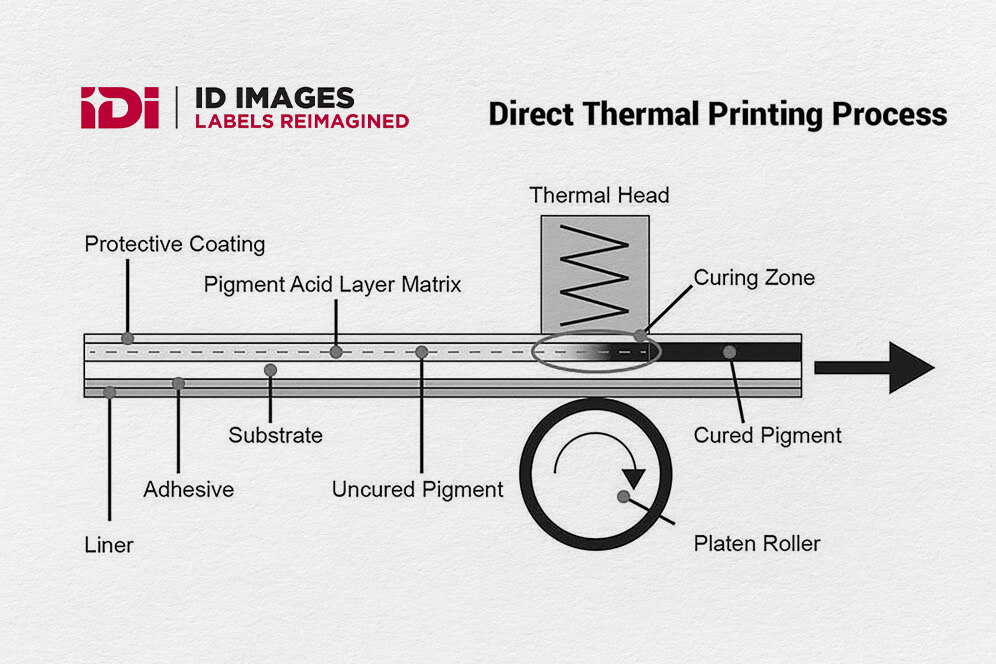

What Makes Direct Thermal Different From Other Labels?

Direct thermal printing technology uses heat-sensitive paper. When passed under a thermal print head, specific areas blacken to form barcodes, text, and graphics without the need for ink, toner, or ribbons. This method provides a straightforward and cost-effective way to produce labels that are crucial for tracking, inventory management, and efficient logistics operations.

Advantages in Transport and Logistics

- Immediate Application: DT labels can be applied to packages immediately after printing, facilitating fast processing and movement within logistic networks.

- Durability: While traditionally considered less durable than other labels, advances in material science have led to direct thermal labels that resist fading, moisture, and abrasion, making them suitable for various environments encountered during shipping and handling.

- Cost-Effectiveness: By eliminating the need for ink, toner, or ribbons, direct thermal printing reduces ongoing operational costs, offering an economical solution for businesses that require high volumes of labels.

- Eco-Friendly Option: Available in recyclable materials, aligning with the growing demand for sustainable business practices.

- Accuracy and Speed: The technology supports high-resolution printing, ensuring barcodes and text are clear and scannable, reducing errors in package handling and tracking. The speed of direct thermal printing supports high-volume output without sacrificing quality.

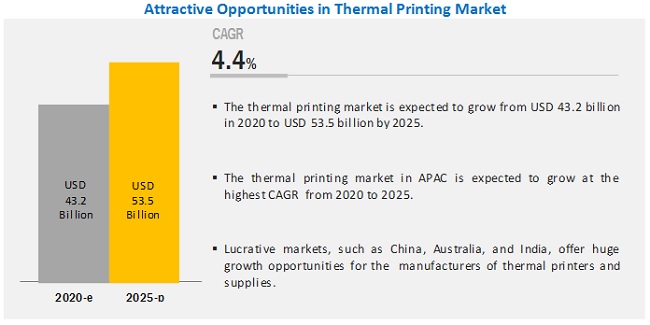

Rising Demand in Transport & Logistics Fuels Thermal Printing Growth

According to a recent study by MarketsandMarkets, the thermal printing market is expected to grow from USD 43.2 billion in 2020 to USD 53.5 billion by 2025; it is expected to grow at a compound annual growth rate (CAGR) of 4.4% during the forecast period. This growth is attributed to the increasing demand for efficient labeling solutions across various industries, especially transport and logistics.

Implementation in Real-World Logistics

From warehousing to last-mile delivery, direct thermal technology has found a wide range of applications. For example, they are instrumental in:

- Warehouse Inventory Management: Quick scanning of labels helps maintain accurate real-time inventory levels.

- Shipping and Receiving: Streamline the shipping and receiving process, ensuring packages are correctly sorted and delivered on time.

- Cold Chain Logistics: With specially designed materials, DT labels withstand extreme temperatures, proving essential for food, pharmaceuticals, and other temperature-sensitive goods

Overcoming Challenges in Transport and Logistics

Despite their many benefits, direct thermal labels can face challenges, such as susceptibility to heat and light over time. However, with the right label materials and protective overlays, these issues can be mitigated, extending the lifespan and utility of the labels in demanding logistic operations. Speak to a label expert today.